“There’s not the perfect product, even the customers know, no one expects it. What is expected instead, is to improve it continuously, listening to those who use it every day”

“There’s not the perfect product, even the customers know, no one expects it. What is expected instead, is to improve it continuously, listening to those who use it every day”

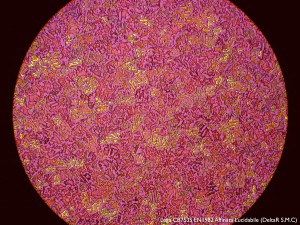

1) Developed materials with great attention to the metallurgical aspects, to the quality and equipment

2) Brass and bronze alloys usually produced according to international specifications and after reformulated for each specific melting process

3) Analytical and micrographic controls for brass and bronze ingots, as well as dimensional, of straightness and test of porosity presence for bronze bars

4) Traceability system od productions made by individual reference samples duly preserved

5) Individual reference samples are obtained by decreasing turning to verify the presence of porosity

Our team made of qualified experts, following a steady work system, is able to satisfy many different customers world-wide, leaders in the various fields of application.

Service Metal Company, in a low-tech sector, as the raw material foundry, has developed materials with great attention to the metallurgical aspects, to the quality and equipment, establishing itself as an industry of ingots for Foundry in copper alloys for the materials of its own production.

Brass and bronze alloys usually produced according to international specifications had been reformulated for each specific melting process and shown in our technical catalogue.

The attention of quality can be easily shown in our research of innovative solutions according to the laws that protect workers and the environment.

Moreover, concerning all incoming metals scrap are submitted to a radiometric control in order to reveal irregular radioactivity levels or or any disused sources from certain materials.